Through a collaborative, team-based methodology, we help our clients develop innovative and transparent decisions which maximizes stakeholder values. We train clients to use Choosing By Advantages (CBA) , which is a decision-making system that enables organizations, project teams and individuals to make more transparent and collaborative decisions. In CBA, decisions are based on importance of advantages. An advantage is the difference between the attributes of two alternatives. For example, in biological systems the fitness of a species is based on its relative competitive advantage to other species within the same ecosystem. By focusing on advantages, CBA connects decisions directly with the context of the decision and the value of the alternatives.

The Last Planner is a collaborative, commitment-based planning system that integrates should-can-will-did. The Last Planner includes pull planning, make-ready look-ahead planning with constraint analysis, weekly work planning based upon reliable promises, and learning. Together, the tools that make up the Last Planner results in more reliable workflow, higher labor productivity, and easier to manage projects. All plans are forecasts and all forecasts are wrong. The longer in the future that on makes a forecast, the greater likelihood that it is wrong. The Last Planner solves this problem by breaking down the project plan into four levels: master schedule, phase schedule, lookahead schedule, and weekly work plan.

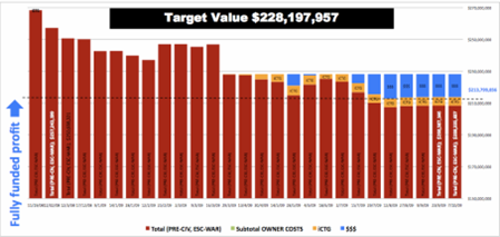

Target Value Design is a disciplined management practice to be used throughout project to assure that the values of the users is delivered within the allowable budget. Research has shown that projects that use Target Value Design have been able to deliver projects below market price and better met the conditions of satisfaction through a more rigorous analysis of cost, value, and worth.

Lean Integrated Project Delivery is a delivery system that seeks to align interests, objectives and practices, by reconceiving the organization, operating system, and commercial terms governing the project. It creates an organization that is best able to apply the principles and practices of the Lean Project Delivery System.

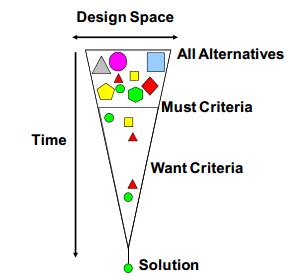

Set-Based Design is a design method in which broadly consider sets of possible solutions and gradually narrow the set of possibilities to converge on a final solution. By setting a wide net from the start, and gradually eliminating weaker solutions, finding the best or better solution becomes more likely. Additionally, backtracking in design due to unforeseen circumstances is less costly since previously developed design tracks can be revisited and further developed instead of starting over from the beginning.

The Plan-Do-Check-Act cycle, also known as the Deming cycle, is a process for continous improvement. PCDA starts with understanding the current state. A future state for improvement is proposed and further data collection is used to validate the improvements. Finally, the process improvement is carried out across the whole organization. Using the PDCA method, projects and organizations can experiment with process improvements ideas using the scientific method of investigation.

2014 © Lean Consulting LLC. ALL Rights Reserved. Privacy Policy | Terms of Service